Armature winding must be connected in series with each other by means of end connections back connection and front connection in a manner so that the generated voltages of the respective coils will aid each other in the production of the terminal emf. When voltage is applied current flows from power supply terminals through the series winding and armature winding.

Its the stationary part containing the field winding and receives the supply.

You can find out more Diagram below

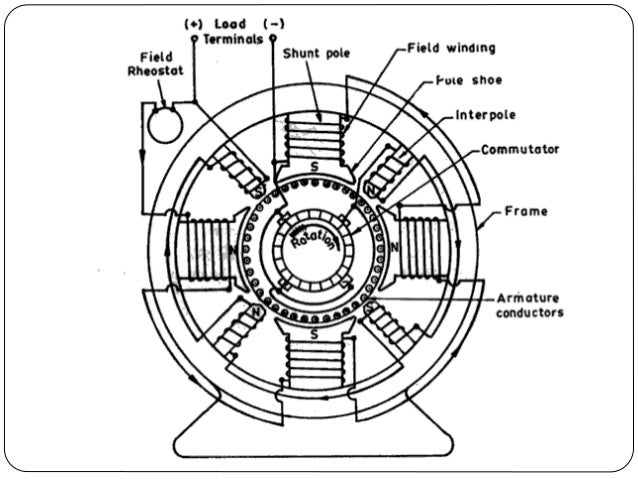

Dc motor winding diagram. A brushed dc motor is an electromechanical motor driven by a dc power source. Construction of dc motor. The commutator of dc motor is a cylindrical structure made up of copper segments stacked together but insulated from each other by mica.

Motor wiring diagram dc. The basic parts of a brushed dc motor are. If a single phase motor is single voltage or if either winding is intended for only one voltage the terminal marking shall be determined as follows.

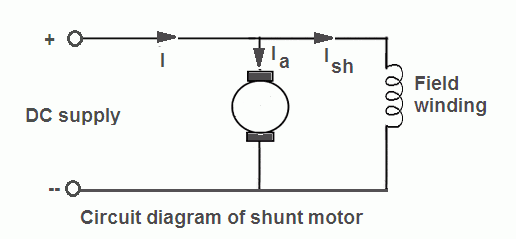

Machine armature windings the different armature coils in a dc. Use figure 2 if your motor has a dual voltage shunt field. Of the windingthis windings are same in both dc motor and dc generator.

Basically armature winding of a dc machine is wound by one of the two methods lap winding or wave winding. Its main function as far as the dc motor is concerned is to commute or relay the supply current from the mains to the armature winding housed over a rotating structure through the brushes of dc motor. Terminal markings and internal wiring diagrams single phase and polyphase motors meeting nema standards b.

Construction of dc motor nearly looks like the construction of dc generator originally when the dc machine starts working we cant identify whether its a dc generator or motor briefly dc motor consists of. Dc series motor circuit diagram in a series motor electric power is supplied between one end of the series field windings and one end of the armature. The diagram below shows this layout in an exploded view of a typical dc motor in this case a small o12mm.

Or leads are connected to the motor windings through the motor brushes. Brushed motors were the first commercially important application of electric power to driving mechanical energy and dc distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Three phase wiring diagrams always use wiring diagram supplied on motor nameplate.

These connections are in accordance with nema mg 1 and american standards publication 06. Always use wiring diagram supplied on motor nameplate. Which is the rotating part.

Use figure 1 if your motor has a single voltage shunt field. Brushes and terminals or leads. The difference between these two is merely due to the end connections and commutator connections of the conductor.

To know how armature winding is done it is essential to know the following terminologies. Motor connections your motor will be internally connected according to one of the diagrams shown below. A brushed dc electric motor is an internally commutated electric motor designed to be run from a direct current power source.

0 comments:

Post a Comment